The Reality of Supply & Demand

The Reality of Supply & Demand

Price increases and order delays. No company wants to be responsible for them, and no buyer wants to be inconvenienced by them.

However, sometimes such occurrences are inevitable, and the magnet production industry is currently struggling with these issues. As a global leader, Adams has been able to limit their impact more than other companies during these industry-wide challenges. But over the past few months even we have not been immune to the realities of the global economic situation.

However, sometimes such occurrences are inevitable, and the magnet production industry is currently struggling with these issues. As a global leader, Adams has been able to limit their impact more than other companies during these industry-wide challenges. But over the past few months even we have not been immune to the realities of the global economic situation.

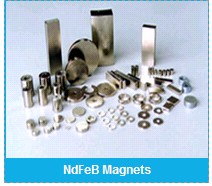

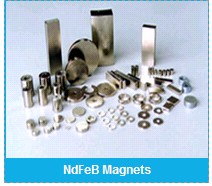

If you've placed an order recently, you may have noticed that we are experiencing price increases and lead time extensions on some of our magnetic assemblies. As a valued customer you deserve to know why these things are happening.

We've expanded our neodymium (Neo) magnetic to include these powerful, compact magnetic discs with adhesive backing and a new, easy pull-tab.

We've expanded our neodymium (Neo) magnetic to include these powerful, compact magnetic discs with adhesive backing and a new, easy pull-tab.

Higher-Priced Materials and Higher Standards

The main driver behind the price hike is raw material costs, especially in iron ore. Annual fixed-price contracts for iron ore are being replaced by a quarterly pricing system that is subject to more cost fluctuation. Also, new higher standards within the magnet industry have resulted in different processing requirements that also contribute to higher costs. However, there is some compensation here in the creation of a higher-quality finished product.

The main driver behind the price hike is raw material costs, especially in iron ore. Annual fixed-price contracts for iron ore are being replaced by a quarterly pricing system that is subject to more cost fluctuation. Also, new higher standards within the magnet industry have resulted in different processing requirements that also contribute to higher costs. However, there is some compensation here in the creation of a higher-quality finished product.

Magnet assembly prices, as well as order fulfillment, have also been impacted by the labor situation in China, where most of Adams' ceramic magnets are manufactured. The Chinese economy is undergoing dramatic growth and transition, which has resulted in greater competition for the nation's workforce.

Other issues have also contributed to our current challenges, including an increase in electric power and coal costs in our factories, and the value of the American dollar against foreign currencies from the nations where our magnets are produced.

Previous:

SUPRISE: Repulsive Magnetic Wo

Next:

Can Magnets Cure Pain??!!!!