We supply: sintered arc NDFEB magnet,segment sintered Neodymium magnet,sintered arc coating NDFEB magnet,arc sintered neodymium magnet

As to sintered arc NDFEB magnet:

1. Materials: Sintered Neodymium-Iron-Boron;

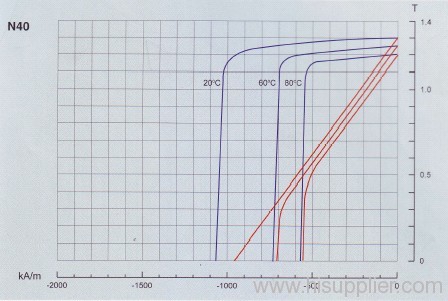

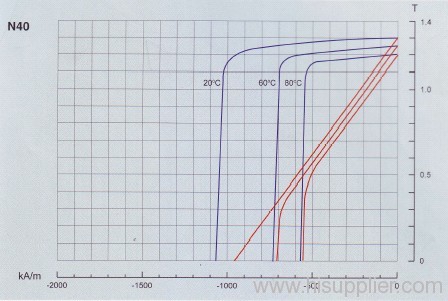

2. Magnetic properties

a) Grades: N33-N52,33M-48M,33H-48H,30SH-45SH,30UH-38UH,30EH-35EH;

b) Curie Temp: 310 °C to 380 °C

c) Max Working Temp: up to 200°C

3. Shapes: Arc/Segment, or others (block, rod, disc, ring etc)

4. Sizes: according to your requests ( R x r X H X Degree );

5. Coatings: Ni, Zn, gold, copper, epoxy, chemical, parylene, etc;

6. Applications: Motors, rotors, sensors, wind turbines/wind generators, loudspeakers, magnetic hooks, magnetic holder, filters automobiles and so on.

7. Certification: ISO9001:2008 .

8. Note: All of our Sintered arc Ndfeb magnet are Customized. Glad to give you any suggestion if you need.

Applications:

Motors, eg. voice coil motor (VCM),step motor, geared down motor, etc.

Features:

Generally speaking, Arc Magnets are all made as Customer Design and as Special requirement. Our factory production and manufacture magnets according to customer's design on shape, dimension, grades, coatings etc.

If you are interested in our sintered arc coating NDFEB magnet,please contact us.We can supply the segment ndfeb magnet as your drawing.

Magnets grade: Full grade,from N35 to N50, from N Series to UH Series.

Magnets drawing with size and shape and different side view

Magnetism direction: Usually magnetized via diameter, if special magnetism direction, please show on the drawing in a

We are supplier of NDFEB BLOCK MAGNETS,or call Neodymium block magnet, block sintered NdFeB Magnet, which can be used as fan generator magnets .

1.NdFeB magnet is The strongest power magnets in all of the permanent magnets. Which can be made in different shape, such as Block sintered NdFeB magnet, Disc sintered NdFeB magnet, etc.

2.Material:Sintered Neodymium-Iron-Boron;

3. The material Grade including: N35 to N52;N35M to N50M;N35H to N48H;N35SH to N45SH;N30UH to N40UH,N30EH to N38EH.Also we can suggest the grade according to where the magnets will be used according to our customer's request.

4. Advanced techniques: Utilizes new Sintered NdFeB magnet techniques and equipment such as strip casting, HDDR technology in our factory to allow us to make high performance NdFeB over N52 possible.

5. The Excellent strength value: the highest (BH)max reaches up to 51MGOe.

6. The Extremely Resistance to demagnetization with Hci,the intrinsic coercive force is over 30000Oe.Neodymium magnet loss -0.09~-0.13% on Br/°C;

7. The moderate temperature stability, their working stability is under 80 degree centigrade for low Hci for NdFeB magnet and above 200 degree centigrade for high Hci NdFeB magnet.

8.Various shapes and sizes or according to customers' requirement; Also we can design the size for our customer's request.

9.Effective Surface treatment to prevent corrosion, such Nickel coating(Ni-Cu-Ni coating);Zinc coating, gold coating, silver coating, tin(Sn) coating, epoxy coating, chemical coating, parylene coating, and so on;

10.Widely used in different application, such as sensors, Motor,rotors, wind turbines/wind generators, loudspeakers, magnetic hooks, magnetic holder, filters automobiles and so on;

11.The quality control: we have our large and expert quality control department and we ensure the magnets ( block sintered NdFeB Magnet,block Neodymium Magnet) from our factory are in high quality.

12.We will provide our customers the test report and BH curves for each item magnets, and also we can do the PCT test ,salt spray test report, aging test report and provide the test report and so on according to our customer's request.

Sintered Neodymium-Iron-Boron magnets are kind of rare earth magnetic material developed recently in1980's, with magnetic properties far exceeding those of the Alnico and Ceramic/Ferrite types. They are alloys of elements, neodymium-iron-boron. The composition is Nd2Fe14B.

Our neodymium disc magnets are mainly used in holding equipment. Some small disc magnets with lower energy are also used in auto speakers.

We can provide low energy neo material with competitive price for holding equipment or auto speakers. But our high energy like N50 or N52 is really powerful for high performance holding equipment.

Raw material--strip casting --hydrogen decrepitation--jet milling--pressing -- sintering -- inspection --machining--surface --magnetizing -- packing --final inspection -- stocking.